ENDPLMC9.xls

Description

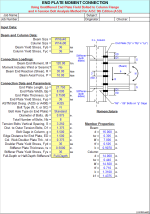

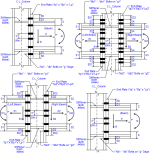

"ENDPLMC9" is a spreadsheet program written in MS-Excel for the purpose of analysis and design of end plate moment connections per the AISC 9th Edition (ASD) Manual. Specifically the program can analyze both single 4-tension bolt and 8-tension bolt configurations, as well as the conditions of having moment connections on each side of the column attached to the column flanges.

This program is a workbook consisting of five (5) worksheets, described as follows:

- Doc - Documentation sheet

- 4-Tension Bolt MC - Single 4-tension bolt end plate moment connection

- (2) 4-Tension Bolt MC's - Double 4-tension bolt end plate moment connections

- 8-Tension Bolt MC - Single 8-tension bolt end plate moment connection

- (2) 8-Tension Bolt MC's - Double 8-tension bolt end plate moment connections

Program Assumptions and Limitations:

1. This program uses the database of member dimensions and section properties from the "AISC Shapes Database", Version 3.0 (2001) as well as the AISC 9th Edition (ASD) Manual (1989).

2. This program is based on the non-seismic specific design procedures found in the following two references:

a. "Moment Connections - End Plate (Static Loading Only)" on pages 4-116 through 4-125 (Static Loading Only)" on pages 4-116 through 4-125, AISC 9th Edition (ASD) Manual (1989).

b. "Extended End-Plate Moment Connections" - AISC Steel Design Guide Series #4, by Thomas M. Murray, PhD, P.E., First Edition (AISC 1990).

c. "Stiffening of Wide-Flange Columns at Moment Connections: Wind and Seismic Applications" - AISC Steel Design Guide Series #13, by Charles J. Carter, P.E., Second Edition (AISC 2003).

3. The original theory used assumes that prying action is negligible and that the tension flange force is equally distributed among the tension bolts. End plates sized according to this AISC procedure herein should result in negligible prying forces at working stress. Thick end plates will result in reduced bolt prying action and are preferred to achieve desired connection rigidity. As a "rule-of-thumb", for end plates with thicknesses greater than or equal to the bolt diameter, prying forces need not be checked.

4. This program contains numerous “comment boxes” which contain a wide variety of information including explanations of input or output items, equations used, data tables, etc. (Note: presence of a “comment box” is denoted by a “red triangle” in the upper right-hand corner of a cell. Merely move the mouse pointer to the desired cell to view the contents of that particular "comment box".)

Calculation Reference

AISC Steel Construction Manual

Calculation Preview

Full download access to any calculation is available to users with a paid or awarded subscription (XLC Pro).

Subscriptions are free to contributors to the site, alternatively they can be purchased.

Click here for information on subscriptions.

Comments: 7

×

hades3

12 years ago

Thanks

17 years ago

In the " ENDPLMC9.xls" and in the 2 worksheets pertaining to a moment connection on only one side of the column, it was brought to my attention that the calculation for the total length of the weld for connecting a pair of stiffeners to the column flange should only have considered the welds on the near side (closest to the beam flange), and not on both ends of the stiffeners, as had been done. This problem did not occur in the 2 worksheets that deal with moment connections on both sides of the column. I also removed the input data validation for the steel yield strengths, which had previously limited the values that could be selected for input. This updated workbook is now version 1.3.

17 years ago

Mark,

Check out the steelutiltiesonline.com forum website. There is a thread there on my ENDPLMC9.xls workbook, and the revisions. I believe that the changes specifically pertained to the bolt shear and tension check calculations. I had tried to get too "cute" with it earlier and realized that there were situations where the #N/A error message occured. What I now did was determine what the allowable bolt shear is (without tension) and subsequently the allowable bolt tension is determined from the AISC interaction formulas. Just copy and paste those related cells, replacing the ones in the earlier version. That should fix you up.

[http://steelutilitiesonline.com/forum/index.php?topic=208.0](http://steelutilitiesonline.com/forum/index.php?topic=208.0)

Alex

Check out the steelutiltiesonline.com forum website. There is a thread there on my ENDPLMC9.xls workbook, and the revisions. I believe that the changes specifically pertained to the bolt shear and tension check calculations. I had tried to get too "cute" with it earlier and realized that there were situations where the #N/A error message occured. What I now did was determine what the allowable bolt shear is (without tension) and subsequently the allowable bolt tension is determined from the AISC interaction formulas. Just copy and paste those related cells, replacing the ones in the earlier version. That should fix you up.

[http://steelutilitiesonline.com/forum/index.php?topic=208.0](http://steelutilitiesonline.com/forum/index.php?topic=208.0)

Alex

17 years ago

Alex,

I was wondering what specific changes you made to the spreadsheet. I modified your previous version to handle an old Fluor Daniel moment connection to include a haunch. I want to be sure of the equations that need to be changed. Is it a simple copy and paste or is it more involved. Thanks in advance!

Mark

I was wondering what specific changes you made to the spreadsheet. I modified your previous version to handle an old Fluor Daniel moment connection to include a haunch. I want to be sure of the equations that need to be changed. Is it a simple copy and paste or is it more involved. Thanks in advance!

Mark

17 years ago

Attached is an update to the "ENDPLMC9.xls" (end plate moment connection) spreadsheet workbook. I added/revised some additional programming logic to eliminate the #NUM! errors that were being displayed in situations where the program was trying to take the square root of a negative number. There were also some bolt size/loading scenarios where a #VALUE! error would be displayed. Again, some additional programming logic was added to eliminate those display errors as well.

I know this stuff is still good old "ASD" and not the AISC 13th Edition, but its tough for some of us (myself included) to let go. Hopefully stuff like this is still an aid in preliminary engineering, estimates, and checking.

I know this stuff is still good old "ASD" and not the AISC 13th Edition, but its tough for some of us (myself included) to let go. Hopefully stuff like this is still an aid in preliminary engineering, estimates, and checking.

17 years ago

Alex,

Recently I was using this spreadsheet (4 Tension Bolt MC tab)and had a question about one of the checks. For local flange bending, you calculate Pfb based on actual flange thickness. Shouldn't this have been Ff instead, therefore rendering Pfb = (4/3) or (5/3) * Ff?

By the way, I love this spreadsheet.

Recently I was using this spreadsheet (4 Tension Bolt MC tab)and had a question about one of the checks. For local flange bending, you calculate Pfb based on actual flange thickness. Shouldn't this have been Ff instead, therefore rendering Pfb = (4/3) or (5/3) * Ff?

By the way, I love this spreadsheet.