Composite Panel Calculations.xlsx

Description

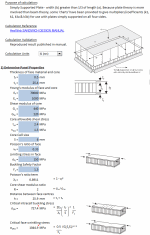

Purpose of calculation:

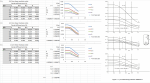

Simply Supported Plate - width (b) greater than 1/3 of length (a). Because plate theory is more involved than beam theory, some 'charts' have been provided to give multipliers/coefficients (k1, k2, k3a & k3b) for use with plates simply supported on all four sides.

Calculation Reference

HexWeb SANDWICH DESIGN MANUAL

Calculation Validation

Reproduced result published in manual.

Calculation Procedure

1) Determine Panel Properties

- Thickness of face material and core

- Young's modulus of face and core

- Shear modulus of core

- Core allowable shear stress

- Core Cell size

- Poisson's ratio of face

- Limiting stress in face

- Buckling Safety Factor

- Poisson's ratio term

- Core shear modulus ratio

- Distance between face centres

- Critical intracell buckling stress

- Critical face wrinkling stress

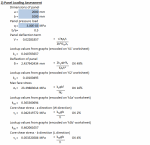

2) Panel Loading Assessment

- Dimensions of panel

- Panel pressure load

- Panel deflection term

- Lookup values from graphs (encoded on 'K1' worksheet)

- Deflection of panel

- Lookup values from graphs (encoded on 'K2' worksheet)

- Max face stress

- Lookup values from graphs (encoded on 'k3a' worksheet)

- Core shear stress - a direction (W direction)

- Lookup values from graphs (encoded on 'k3b' worksheet)

- Core shear stress - b direction (L direction)

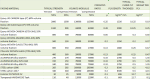

SELECT FACING MATERIAL FROM LOOKUP TABLE

- Epoxy UD CARBON tape (0°) 60% volume fraction

- Epoxy UD GLASS tape (0°) 55% volume fraction

- Epoxy WOVEN CARBON (G793-5HS) 55% volume fraction

- Epoxy WOVEN ARAMID (285K-4HS) 60% volume fraction

- Epoxy WOVEN GLASS (7781-8HS) 50% volume fraction

- Phenolic WOVEN GLASS (7781-8HS) 55% volume fraction

- ALUMINIUM Alloy 2024 T3

- ALUMINIUM Alloy 5251 H24

- ALUMINIUM Alloy 6061 T6

- STEEL carbon 1006

- STEEL carbon 1017

- Exterior PLYWOOD Fir

- Tempered HARDWOOD Teak

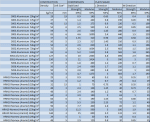

SELECT CORE MATERIAL FROM LOOKUP TABLE

- 3003 Aluminium 29kg/m³

- 3003 Aluminium 37kg/m³

- 3003 Aluminium 42kg/m³

- 3003 Aluminium 54kg/m³

- 3003 Aluminium 59kg/m³

- 3003 Aluminium 83kg/m³

- 5052 Aluminium 37kg/m³

- 5052 Aluminium 50kg/m³

- 5052 Aluminium 54kg/m³

- 5052 Aluminium 72kg/m³

- 5052 Aluminium 83kg/m³

- 5052 Aluminium 127kg/m³

- 5052 Aluminium 130kg/m³

- 5056 Aluminium 37kg/m³

- 5056 Aluminium 50kg/m³

- 5056 Aluminium 50kg/m³

- 5056 Aluminium 72kg/m³

- HRH10 Nomex (Aramid) 29kg/m³

- HRH10 Nomex (Aramid) 32kg/m³

- HRH10 Nomex (Aramid) 32kg/m³

- HRH10 Nomex (Aramid) 48kg/m³

- HRH10 Nomex (Aramid) 48kg/m³

- HRH10 Nomex (Aramid) 64kg/m³

- HRH10 Nomex (Aramid) 64kg/m³

- HRH10 Nomex (Aramid) 80kg/m³

- HRH10 Nomex (Aramid) 96kg/m³

- HRH10 Nomex (Aramid) 123kg/m³

- HRH10 Nomex (Aramid) 144kg/m³

- HRH10 Nomex (Aramid) 29kg/m³

- HRH10 Nomex (Aramid) 48kg/m³

Calculation Reference

Composites Design

Composite Materials

Composite structures

Calculation Preview

Full download access to any calculation is available to users with a paid or awarded subscription (XLC Pro).

Subscriptions are free to contributors to the site, alternatively they can be purchased.

Click here for information on subscriptions.

Comments: 1

×

The error you describe is [#VALUE](https://office.microsoft.com/en-gb/excel-help/correct-a-value-error-HP010342330.aspx) which does not suggest that the problem is with XLC. Follow the link to try to diagnose your problem.