Pressure Sand Filter & Activated Carbon Filter Vessel & Media Calculation for Water & Wastewater Treatment Plant

Description

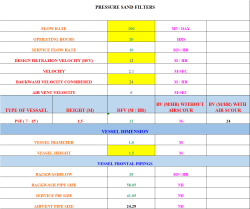

1. Working Principles

Pressure Sand Filter

- Uses a bed of graded sand/gravel media in a pressurized vessel

- Water flows downward through media layers under pressure

- Removes suspended solids, turbidity, and particulate matter

- Typical media arrangement (top to bottom):

- Fine sand (0.5-1.0 mm)

- Coarse sand (1-2 mm)

- Fine gravel (2-4 mm)

- Coarse gravel (4-8 mm)

Activated Carbon Filter

- Uses activated carbon media in a pressurized vessel

- Removes organic compounds, chlorine, odor, and taste

- Works through adsorption process

- Types of carbon:

- Granular Activated Carbon (GAC)

- Powdered Activated Carbon (PAC)

2. Key Design Parameters & Calculations

A. Vessel Size Calculations

- Filter Area (A) calculation:

A = Q / DFV

Where:

A = Filter area (m²)

Q = Flow rate (m³/hr)

DFV = Design Filtration Velocity (m/hr)

- Vessel Diameter (D) calculation:

D = √(4A/π)

Where:

D = Diameter (m)

A = Filter area (m²)

- Media Bed Height:

- PSF: Typically 0.9-1.2m

- ACF: Typically 1.0-1.5m

B. Backwash System Design

- Backwash Flow Rate:

Qbw = A × Vbw

Where:

Qbw = Backwash flow rate (m³/hr)

A = Filter area (m²)

Vbw = Backwash velocity (m/hr)

- Air Scour Rate:

Qair = A × Vair

Where:

Qair = Air flow rate (m³/hr)

A = Filter area (m²)

Vair = Air velocity (m/hr)

C. Operating Parameters

- Service Flow Rate:

SFR = Q / A

Where:

SFR = Service Flow Rate (m³/m²/hr)

Q = Flow rate (m³/hr)

A = Filter area (m²)

- Daily Treatment Capacity:

DTC = Q × Operating Hours

Where:

DTC = Daily Treatment Capacity (m³/day)

Q = Flow rate (m³/hr)

3. Design Considerations

Typical Design Values

- Design Filtration Velocity (DFV): 10-15 m/hr for PSF, 8-12 m/hr for ACF

- Backwash Velocity: 30-45 m/hr for PSF, 25-35 m/hr for ACF

- Air Scour Velocity: 50-60 m/hr

- Operating Hours: Usually 16-24 hrs/day

- Service Flow Rate: Should not exceed maximum recommended by media manufacturer

Safety Factors

- Vessel Height:

- Add 40-50% to media height for expansion during backwash

- Additional 20% freeboard for water distribution

- Pressure Rating:

- Design pressure: typically 3-6 bar

- Test pressure: 1.5 × design pressure

Important Notes

- Media Specifications:

- Use proper gradation for even flow distribution

- Ensure media meets AWWA standards

- Consider local water quality for media selection

- Maintenance Requirements:

- Regular backwashing schedule based on pressure drop

- Media replacement every 3-5 years for PSF

- GAC replacement based on breakthrough (typically 1-3 years)

Calculation Preview

Full download access to any calculation is available to users with a paid or awarded subscription (XLC Pro).

Subscriptions are free to contributors to the site, alternatively they can be purchased.

Click here for information on subscriptions.