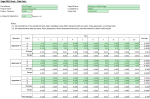

Anova Gage Repeatability & Reproducibility

Description

Manufacturers are continually striving to improve product and process quality and reduce part variation in their processes. The fact is variation exists in every manufacturing process. The common method that many design engineers use to address variance is to assign a tolerance range to their print dimensions. The manufacturing processes are then monitored through the application of Statistical Process Control (SPC) methodology including regular data collection intended to keep the process in a “state of control”. The success of any SPC system depends upon precise and accurate data. Unfortunately, all measurement data contains a certain percentage of variation. The variation is the difference between the true values and the observed values. The variation represents the amount of measurement error. In addition to measurement error, is the actual product or process variation. When we combine measurement error with product or process variation the resulting value represents the total variation. To assure that our measurement data is accurate we must determine if the amount of variation is acceptable. An effective tool for evaluating measurement variation is Gage Repeatability and Reproducibility (Gage R & R).

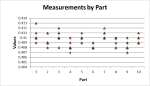

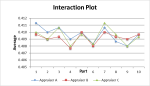

Calculation Preview

Full download access to any calculation is available to users with a paid or awarded subscription (XLC Pro).

Subscriptions are free to contributors to the site, alternatively they can be purchased.

Click here for information on subscriptions.