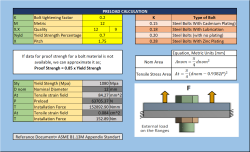

Preload Calculator

Description

This calculation, based on the ASME B1.1 Appendix B standard, is designed to determine the preload force and tightening torque for bolts. By utilizing parameters such as bolt diameter, material grade, and other necessary inputs, it provides the required preload values to ensure the safety and durability of the connection. This helps minimize the risks of loosening, leakage, or damage in bolted connections, enhancing the reliability of mechanical systems.

For metric threaded fasteners according to ASME B1.13M:

- Yield Strength (Sty) in MPa:

- This is a material property that depends on the fastener grade/class

- Used as the base value for calculating allowable stresses

- For most calculations, a safety factor is applied to Sty

- Nominal Diameter (D nom):

- The basic major diameter of the external thread

- Used as reference for calculating:

- Thread stress area (As)

- Thread engagement length

- Various thread dimensions

- Preload (P):

- Calculated as: P = K × At × Sty Where:

- K is the preload factor (typically 0.75 for reusable connections)

- At is the tensile stress area

- Sty is the yield strength

- Installation Force/Torque (T):

- T = K × P × D nom Where:

- K is the nut factor (typically 0.15-0.25 depending on lubrication)

- P is the preload force

- D nom is the nominal diameter

The tensile strain field affects both preload and installation calculations through:

- Modified stress distributions

- Changes in effective thread engagement

- Potentially altered friction coefficients

Calculation Preview

Full download access to any calculation is available to users with a paid or awarded subscription (XLC Pro).

Subscriptions are free to contributors to the site, alternatively they can be purchased.

Click here for information on subscriptions.

Comments: 2

×

d nominal should be d mean (10.86 mm)