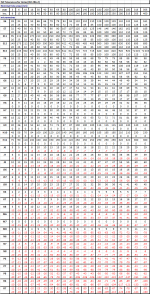

Dimensional Tolerances ISO 286-2

Description

Purpose of calculation

Calculate upper and lower limits for shafts and holes (bores).

Calculation Validation

5 selections have been checked manually.

Calculation Units - mm

| Fit | Preferred | All | Description | Use |

| Clearance | H11/c11, C11/h11 | H11/a11, H11/c11, H11/c9, H11/d11, A11/h11, C11/h11, D11/h11 | Fits with great clearances with parts having great tolerances. | Pivots, latches, fits of parts exposed to corrosive effects, contamination with dust and thermal or mechanical deformations. |

| Clearance | H9/d9, D10/h9 | H9/C9, H9/d10, H9/d9, H8/d9, H8/d8, D10/h9, D9/h9, D9/h8 | Running fits with greater clearances without any special requirements for accuracy of guiding shafts. | Multiple fits of shafts of production and piston machines, parts rotating very rarely or only swinging. |

| Clearance | H9/e9, H8/e8, E9/h9 | H9/e9, H8/e8, H7/e7, E9/h9, E8/h8, E8/h7 | Running fits with greater clearances without any special requirements for fit accuracy. | Fits of long shafts, e.g. in agricultural machines, bearings of pumps, fans and piston machines. |

| Clearance | H8/f7, H7/f7, F8/h6 | H9/f8, H8/f8, H8/f7, H7/f7, F8/h7, F8/h6 | Running fits with smaller clearances with general requirements for fit accuracy. | Main fits of machine tools. General fits of shafts, regulator bearings, machine tool spindles, sliding rods. |

| Clearance | H7/g6, G7/h6 | H8/g7, H7/g6, G7/h6 | Running fits with very small clearances for accurate guiding of shafts. Without any noticeable clearance after assembly. | Parts of machine tools, sliding gears and clutch disks, crankshaft journals, pistons of hydraulic machines, rods sliding in bearings, grinding machine spindles. |

| Clearance | None | H11/h11, H11/h9 | Slipping fits of parts with great tolerances. The parts can easily be slid one into the other and turn. | Easily demountable parts, distance rings, parts of machines fixed to shafts using pins, bolts, rivets or welds. |

| Clearance | H7/h6 | H8/h9, H8/h8, H8/h7, H7/h6 | Sliding fits with very small clearances for precise guiding and centring of parts. Mounting by sliding on without use of any great force, after lubrication the parts can be turned and slid by hand. | Precise guiding of machines and preparations, exchangeable wheels, roller guides. |

| Transition | H7/j6 | H8/j7, H7/js6, H7/j6, J7/h6 | Tight fits with small clearances or negligible interference. The parts can be assembled or disassembled manually. | Easily dismountable fits of hubs of gears, pulleys and bushings, retaining rings, frequently removed bearing bushings. |

| Transition | H7/k6, K7/h6 | H8/k7, H7/k6, K8/h7, K7/h6 | Similar fits with small clearances or small interferences. The parts can be assembled or disassembled without great force using a rubber mallet. | Demountable fits of hubs of gears and pulleys, manual wheels, clutches, brake disks. |

| Transition | H7/n6, N7/h6 | H8/p7, H8/m7, H8/n7, H7/m6, H7/n6, M8/h6, N8/h7, N7/h6 | Fixed fits with negligible clearances or small interferences. Mounting of fits using pressing and light force. | Fixed plugs, driven bushings, armatures of electric motors on shafts, gear rims, flushed bolts. |

| Interference | H7/p6, H7/r6, P7/h6 | H8/r7, H7/p6, H7/r6, P7/h6, R7/h6 | Pressed fits with guaranteed interference. Assembly of the parts can be carried out using cold pressing. | Hubs of clutch disks, bearing bushings. |

| Interference | H7/s6, S7/h6 | H8/s7, H8/t7, H7/s6, H7/t6, S7/h6, T7/h6 | Pressed fits with medium interference. Assembly of parts using hot pressing. Assembly using cold pressing only with use of large forces. | Permanent coupling of gears with shafts, bearing bushings. |

| Interference | None | H8/u8, H8/u7, H8/x8, H7/u6, U8/h7, U7/h6 | Pressed fits with big interferences. Assembly using pressing and great forces under different temperatures of the parts. | permanent couplings of gears with shafts, flanges. |

Calculation Reference

Machinery's Handbook

ISO 286-2 Tolerances for Shafts & Holes

Machine Design

Calculation Preview

Full download access to any calculation is available to users with a paid or awarded subscription (XLC Pro).

Subscriptions are free to contributors to the site, alternatively they can be purchased.

Click here for information on subscriptions.

Be the first to comment! Please sign in or register.

×