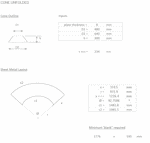

Cone Unfolding

Description

Simple MS-Excel spreadsheet to calculate a sheet metal cone unfolding. In pressure vessel design, particularly for vessels with conical sections, engineers often use cone unfolding calculations to determine the dimensions of flat patterns that can be cut from sheet metal and formed into the conical shape required for the vessel. This process is crucial for accurately fabricating the conical sections of the vessel from flat sheets.

Here's a step-by-step description

of how cone unfolding calculations are typically performed:

-

Define the Conical Section Parameters: Engineers start by specifying the dimensions and properties of the conical section of the pressure vessel. This includes the cone's base diameter (D), top diameter (d), height (H), and any taper angle.

-

Calculate the Slant Height (l): Using geometric relationships, the slant height (l) of the conical section is calculated. The slant height is the straight-line distance from the apex of the cone to any point on its circumference.

-

Determine the Arc Length (C): The arc length (C) of the base of the conical section is calculated using the base diameter (D) and the formula for the circumference of a circle (C = π * D).

-

Calculate the Development Length (L): The development length (L) of the conical section is determined by applying trigonometric relationships. This involves calculating the length along the curved surface of the cone from the apex to the base.

-

Unfold the Cone: Using the calculated development length (L), engineers create a flat pattern by 'unfolding' the conical section onto a 2D plane. This flat pattern represents the shape of the sheet metal that will be cut and formed to create the conical section.

-

Add Allowances for Bending and Flange Formation: Engineers typically add allowances for bending and flange formation to the flat pattern to account for material stretching and deformation during fabrication. These allowances ensure that the final formed cone matches the desired dimensions and shape.

-

Transfer the Flat Pattern to Sheet Metal: The unfolded flat pattern is then transferred onto a sheet of metal, such as steel or aluminum, using layout tools and cutting equipment. Careful marking and cutting are essential to ensure accuracy and precision in fabricating the conical section.

-

Form the Conical Section: Finally, the flat pattern is formed into the desired conical shape using techniques such as rolling, bending, welding, and/or riveting. The formed conical section is then assembled with other components to complete the pressure vessel.

By performing cone unfolding calculations, engineers can accurately fabricate conical sections for pressure vessels, ensuring proper fit, functionality, and structural integrity in the final product. These calculations are essential for achieving precise dimensions and shapes required for safe and efficient operation of pressure vessels in various industrial applications.

Calculation Preview

Full download access to any calculation is available to users with a paid or awarded subscription (XLC Pro).

Subscriptions are free to contributors to the site, alternatively they can be purchased.

Click here for information on subscriptions.